TEK DEALER TOOLS

AND TECHNICAL RESOURCES

When Tek Industries brings a new roofing company into our family of partners and clients, we want everyone to succeed and progress.

WHY ROOFING COMPANIES SHOULD PARTNER WITH TEK INDUSTRIES AND EXPAND TO A DEALER ROLE

An exclusive opportunity is on hand, provided by TEK® Industries for roofing materials dealers across the nation. This new event gives you direct access to the best metal shake products on the market. By avoiding an additional distributor, it lets you purchase at a reduced price, then pass those savings on to your customers. This opens the way for increased orders and increased profits.

When TEK® Industries brings a new roofing company into our family of partners and clients, we want everyone to succeed and progress. That’s why we’re helping companies that have traditionally focused on fixing roofs now expand their vision and diversify their profit-making. With the exclusive access to the best-of-class roofing materials that we provide, you can make waves in the roofing industry. You will be able to supply other roofers with high quality metal shake and, just as easily, provide outstanding deals for the customers who want to work with you directly. These new opportunities are possible when you become part of the TEK® Industries family.

Additional Resources

INSTALLATION METHODS

Step by step install methods for Metal Pro-X Hip Cap and hip flashing installation.

HURRICANE® METAL SHAKE

HURRICANE® METAL SHAKE PRO

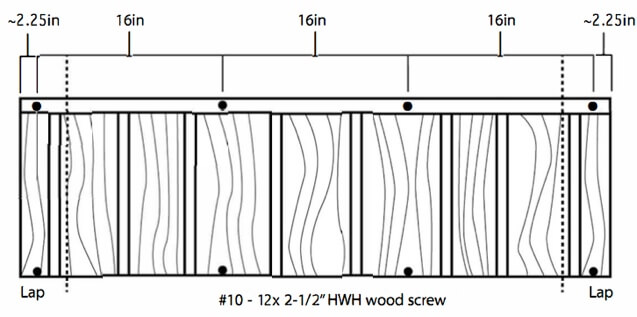

HURRICANE® Metal Shake

| Minimum roof pitch | 3:12 |

| Panel size | 52-1/2” X 16-1/2” |

| Installed exposure | 50-3/4” X 14-1/2” |

| Panels per square | 20 |

| Installed Weight | 145.5 lbs/sq |

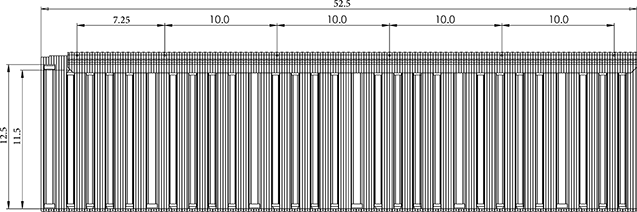

HURRICANE® Metal Shake PRO

| Minimum roof pitch | 3:12 |

| Panel size | 50-1/2” X 14-1/2” |

| Installed exposure | 48-3/4” X 13-1/2” |

| Panels per square | 23 |

| Installed Weight | 145.5 lbs/sq |

Certifications

Texas Department of Insurance

Other Specs

- ASTM A792

- ASTM B117

- ASTM E108

- ASTM G155

- CCRR-0443

Florida Building Code

- UL 580 Class 90

- UL 1897

- Florida Building Code Approved #FL38136